Surface Preparation

Preparing your metal parts for a flawless finish

When it comes to powder coating metal parts, surface preparation is critical. Sandblasting not only eliminates debris and contaminants but also creates the ideal texture for the powder to bond with the surface of your parts and components.

Our sandblasting service provides a consistent and uniform finish that optimizes the performance and aesthetic of the powder coating. A well-prepared surface reduces the chances of defects and uneven coating, ensuring that your parts are not only protected but look great for years to come.

Reliable Service

Getting the job done, rain or shine

We understand that deadlines are crucial, which is why we have an enclosed outdoor Sandblasting station, ensuring we can get your parts and components prepared for powder coating even when it’s raining or snowing.

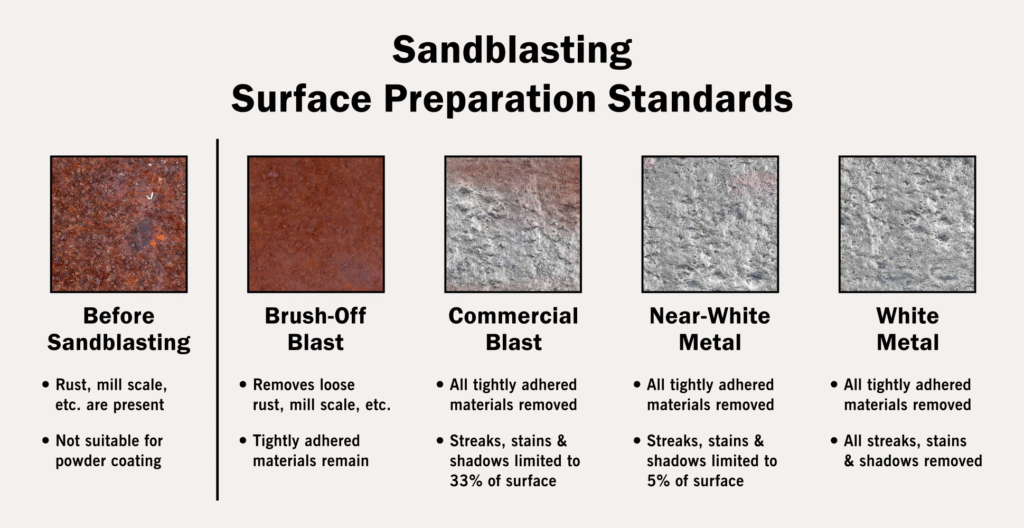

Sandblasting Standards

Choosing the right surface preparation for your parts

There are multiple sandblasting surface preparation standards to choose from. All of these standards will roughen the surface of your metal parts to prepare them for coating. More extensive blasting can increase coating life, but also requires more time and thus a higher cost, so a balance must be struck.

In order from least intense to most, the standards are Brush-off Blasting, Commercial Blasting, Near-White Metal, and White Metal. We will help you make the right choice for your parts, depending on your budget and the environment they will be placed in.